Wile doing a recent oil change, I discovered that the original rubber coolant hoses had started to bubble. This meant that the car was getting parked until I could replace the hoses because I knew they were ticking time bombs. These bubbles were more than likely caused by oil within the coolant lines, which I know was caused by a failed DSG cooler last year. Even though I did a very thorough flush, the damage had already been done and not all of the oil was evacuated.

Once I looked up the prices for the OEM replacement hoses, it was an easy decision to purchase silicone hoses. The OEM hoses were well over $500 at my wholesale cost…hell no. Now, for silicone, there are two companies that offer a kit for the Mk5 R32: Forge Motorsport and Addiction Motorsport. Both companies are located in the UK (Forge has a US location) and both offer the kits in three different colors. However, Forge’s kit is meant specifically for a manual transmission R32 (Europe only option) but AM’s kit is for a DSG R32. Seems like a simple solution, right?

Wrong. Addiction Motorsport was out of stock of their black kit, which is the color I wanted, and through speaking with them via email (very quickly I will add), I was told that it would end up being about 3-4 weeks before they had it back in stock. With Wookies in the Woods fast approaching (4 weeks from when I contacted them), they were no longer an option for me, which is unfortunate because I really do like the look of their kit and the fact that is meant for a DSG car. Instead, I ordered a black Forge kit, knowing that it came with no instructions, additional data, and that modification would be necessary to work with a DSG car.

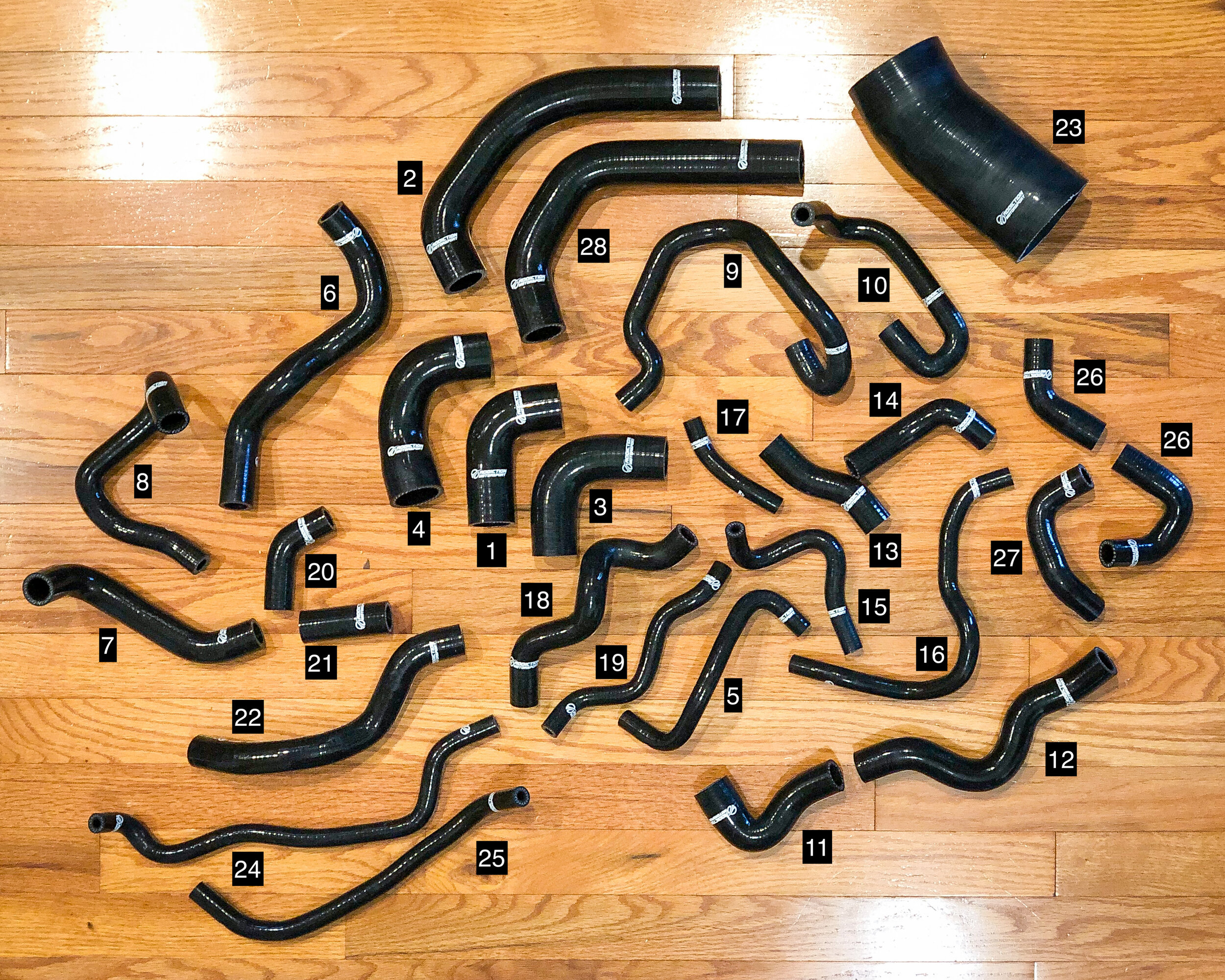

The kit showed up quickly and did include nice hose clamps. I had called Forge Motorsport US when I ordered them to see if they knew what else was needed in addition to the kit and was flat out told no and that they don’t know. I mocked up all the hoses to start figuring this out since there aren’t any documented DIY or informational posts that I could find. This leads us to what you are reading now. Because Forge doesn’t tell you what is what, I am here to help you save time.

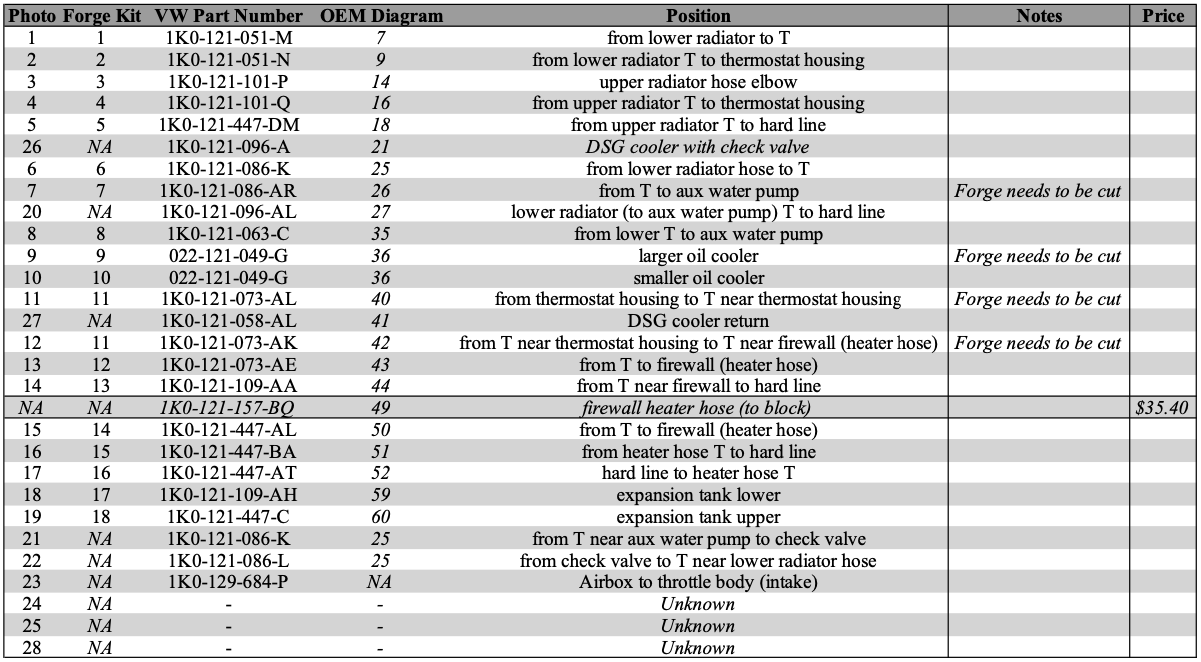

Each hose has a three digit stamp on it (I really hope they all do and that they are all the same) and I made a spreadsheet showing each hose and it’s corresponding OEM part number, location, and which hoses are missing from the kit.

Now, I am not going to do a full actual DIY because, well, it is a lot and not a small task. What I will say is that you will need to put the radiator support into the service position at a minimum in order to get two hoses (one from the oil cooler to the block and one from the aux water pump to the block). In addition, you will need remove the thermostat housing and water pipe (aka the crack pipe) in order to get to those same hoses. Everything else can be accessed with just the intake out of the way. You will notice that there are four lines that say “needs to be cut” and it is not that intimidating so long as you have a sharp knife. You simply need to lay the hose next to it’s corresponding OEM hose and mark where the breaks need to happen. Also, don’t forget to transfer any heat shield, bumper, or sleeves from the OEM hoses to the new hoses: they’re there for a reason.

I will also mention that the longer oil cooler hose (goes to the block) is not the same shape as the OEM hose but can work, once the larger end is trimmed. I would have to look up why this is…possibly the manual R32 has a different cooler if I had to guess. I was also told by three people that they were able to modify one of the Forge hoses to work with the DSG cooler but no matter what configuration I tried, I could not figure this out. This is why I have the OEM hoses for that listed, as well as a new heater hose (really weird that it wasn’t replaced with the Forge kit), and one smaller hose on the lower radiator line that connects the DSG cooler to the system.

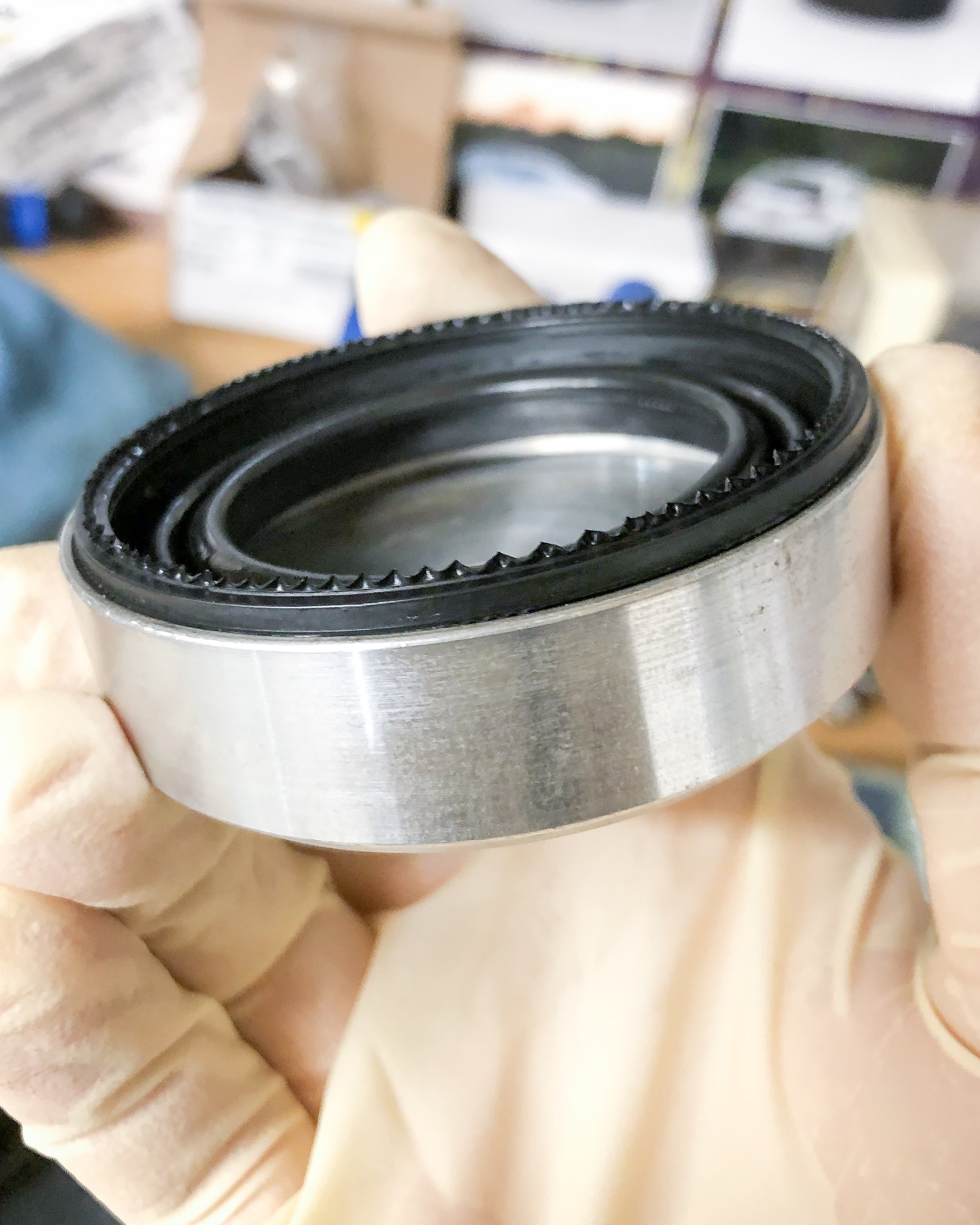

For me, since everything was open and there was still residual oil in the system, a full flush using Volkswagen’s Clean Sol (G-052-188-A3) will be done. I used this last year and I will say that it does a really good job. It is tedious to do a full flush but I don’t want to do any of this again for a long time.

Time to talk turkey: the Forge kit costs $400 (sales, free shipping, and hose clamps are available depending on where you order from) and the four missing hoses will cost $145.27 MSRP from a dealer. The Addiction Motorsport kit is listed on their site 315.99 £ ($458.44) but that does include their VAT for UK buyers. In talking with them via email, they will remove the VAT for US buyers with proof of residence. This makes their kit 263 £ ($381.56) plus shipping (25 £ or $36.27) and this means (in theory) you will not need to buy the extra OEM hoses, although I cannot verify this because I do not have their kit in front of me. Perhaps I will buy their kit just for a comparison, though I will not install after I have already gone through all this trouble.

If time wasn’t an issue, I would have waited for the black Addiction Motorsport kit to get back in stock (yes, even if the prices were identical). I also do not know if they provide clamps and any further information or instructions with their kit but I think it is worth the savings in price and hassle of having to modify. I hope this helps and if you need any more information, don’t hesitate to ask.

UPDATE!

Once the Addiction Motorsport hoses in black were available, I did order them, for science. Man, I really wish these would have been available when I was doing the job but now I know for the future and so will all of you.

I see no physical issues with the kit and they also come with no instructions or information as to what is what. One major downside to this kit is there are no identifying marks like the Forge kit so there is no way for me to list what is what like I did with them. What I can do is get as close as I can to comparing them:

As you can see from the chart, I am clueless as to the locations of three hoses (24, 25, and 28) and honestly, I am not taking my car apart to figure that out. If you purchase this kit and figure it out, please let me know. I also could be wrong but I do not see a hose to replace one of the two heater core hoses, which the Forge kit also does not provide.

I hope this helps and I do have the hoses listed for sale (click HERE for the listing) for someone that needs the kit in the States. I am losing a little money in the name of documenting as much as possible for the Mk5 R32 coolant hose replacements.