I know I normally publish on Tuesdays and Thursdays but this is fresh in my head so here we go!

Since putting on the Nokian Rotiivas, my speedometer has been off about 8% from my actual speed due to them being larger than OEM. This may seem like a no brainer to just go slower. True, that is an option but not something I want to calculate while driving. I found some useful information today and put it to the test and was pleasantly surprised with the results. Simply, you have to change the coding of the Instruments and I did this with VCDS. Before I get to the coding, you need to understand the sizing and impulses being read.

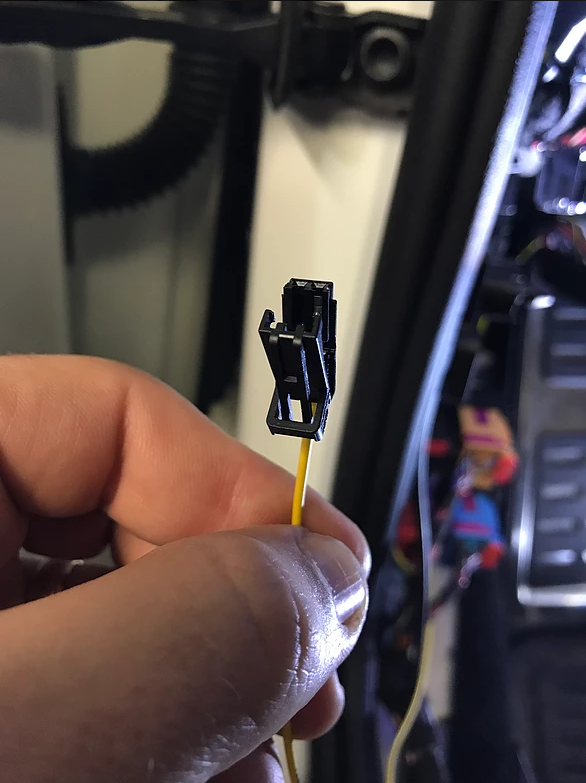

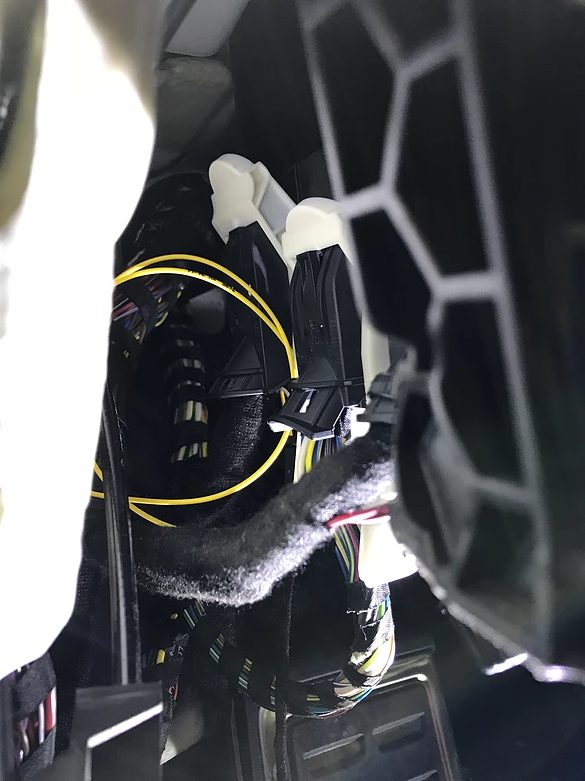

When the wheels spin, the ABS sensors measure the rotations and send an impulse to the computer via witchcraft/magic. The computer is programmed to take those impulses and convert them to the speedometer with a set formula that is set with coding.

The 215/65R16 tires that I am running break down to this: a diameter of 27" (685.8 mm) and a circumference of 84.84" (2,154.936 mm). There are 43 impulses per revolution and the math I found in order to figure out the revolutions per kilometer, is 1,000,000/circumference (in millimeters). So with this tire, there are 464.05 revolutions per kilometer and 19,954.15 impulses per kilometer. With all of that known, this chart I found was very helpful:

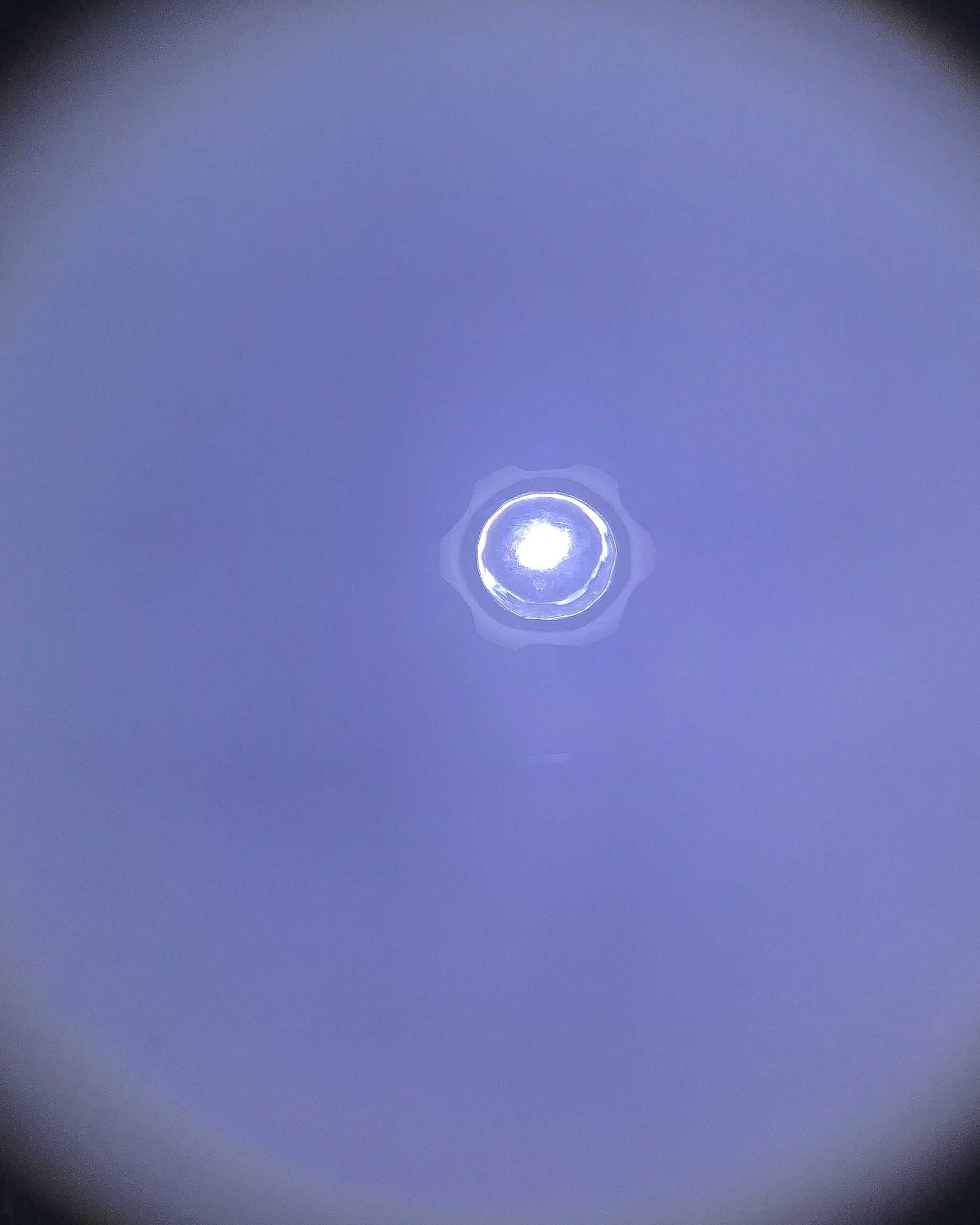

The file was a read only document so I couldn't change the numbers up top but the formulas were there and the important information is on the bottom. Of the numbers shown the one column closest to my numbers were column 4, and when I coded the car to that, my speedometer was where it needed to be. Now to the coding; it is simple.

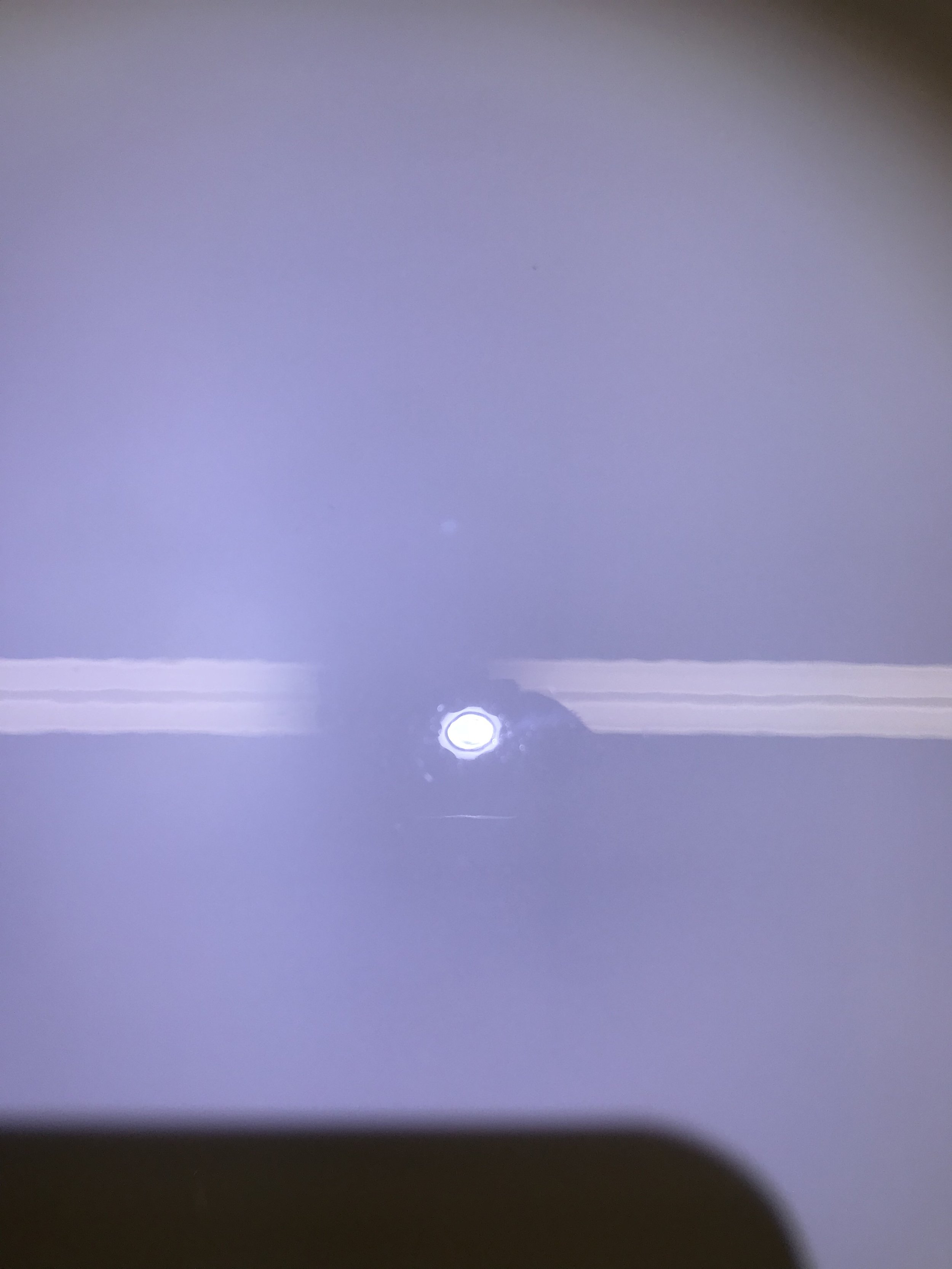

Using VCDS, access the Instruments group 17.

Select Coding and then Long Coding Helper. Once in, toggle over to Byte 3 (the fourth little box with numbers in it). You should see the screen above. The drop down menu from the factory should have 05 Tire Circumference: Variant 6 selected. Click on the drop down menu and select 03 Tire Circumference: Variant 4.

Close the window and select the Do It! button. That's it!

Please, take notice of your stock settings so that if it doesn't work you can revert back. This worked for me and I am really happy to have a normal speedometer/actual speed.